The safety barrier is connected between intrinsically safe circuits and non intrinsically safe circuits. A device that limits the voltage or current supplied to intrinsically safe circuits to a certain safety range. In some special industrial sites such as gas companies and chemical plants, it is not only necessary to use a two-wire transmission system, which provides both power distribution and signal isolation functions, but also has safety spark explosion-proof performance, reliably curbing the power supply, preventing ignition between the power supply, signal, and ground, and limiting current and voltage drops to restrict signals and power circuits, limiting the energy entering hazardous locations within the safety quota。

|

|

|

|

P+F Beijiafu safety barrier

|

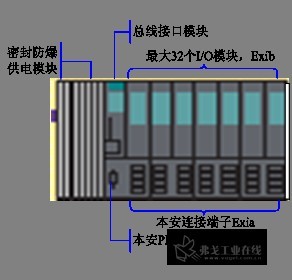

Structural drawing of safety barrier

|

It is well known that chemical enterprises are high-risk enterprises, and are prone to major accidents such as explosions during production and operation. Explosion occurs when the following three conditions are met simultaneously on site: ① explosive substances such as explosive gases; ② Oxygen; ③ An ignition source, such as a spark of sufficient energy or a sufficiently high surface temperature of an object. This is the so-called explosive triangle principle

|

|

|

Explosion Triangle Principle

|

According to the explosion triangle principle, eliminating any of the above three conditions can prevent explosion. Oxygen is difficult to control, so controlling explosive substances and detonating sources are the two most commonly used methods of explosion prevention. The safety barrier technology is based on the principle of controlling the detonation source. The so-called controlled detonation source refers to the artificial elimination of the detonation source, i.e., the elimination of sufficient sparks for detonation and the elimination of sufficient instrument surface temperature rise. That is, the use of safety barrier technology to limit the electrical energy provided to on-site instruments to neither generate sufficient sparks nor generate sufficient instrument surface temperature rise for detonation. According to international standards and Chinese national standards, when any equipment connected to the safety zone side of the safety barrier fails (the voltage does not exceed 250 V), the intrinsically safe explosion-proof method can ensure explosion-proof safety on site. For instrument detection and control loops, to ensure on-site safety, it is necessary to limit on-site energy, which means limiting voltage and current. Because capacitors and inductors can store and release energy, they also need to be limited. The commonly used electric energy detonation curves given in international standards and Chinese national standards include voltage current detonation curves, voltage capacitance detonation curves, and current inductance detonation curves. Based on these curves and considering a safety factor of 1.5 times, one can determine the electrical energy limiting parameters for a specified circuit when a certain type of gas is involved. For example, when Class IIC gases (such as hydrogen) are involved, the voltage limit for circuits with a nominal 24 V (DC) power supply (such as transmitters, electrical converters, solenoid valves, etc.) is usually set to 28 V. Based on this voltage limit value, check the voltage current detonation curve, and consider a 1.5 times safety factor to determine that the current limit value at this time should be 119 mA. The restriction of energy reaching the site can be accomplished through safety barriers.

Safety barriers, also known as safety energy limiters, are an important component of intrinsically safe systems. Safety barriers mainly include Zener type safety barriers and isolation type safety barriers. The core components of the Zener safety barrier are Zener diodes, current limiting resistors, and fast fuse links. Isolated safety barriers not only have limited energy functions, but also have isolation functions. They are mainly composed of loop energy limiting units, signal and power isolation units, and signal processing units. The main function of safety barriers is to limit current and voltage, ensuring that the energy available to field instruments is within a safe range。

。

|

|

|

P+F Beijiafu explosion-proof safety barrier

|

The petrochemical industry is currently one of the more widely used industries in the field of automation products. In the petrochemical industry, mainstream automation products, such as DCS, PLC, control valves, and various field instruments, will be widely used. However, the connection and safety between various instruments and between instruments and field equipment require careful protective measures. Therefore, in recent years, Safety barriers are widely used in petrochemical industry. Some of the customers who have cooperated with our company for a long time include China National Petroleum Corporation, Daqing Petroleum Technology Development Co., Ltd., North China Petroleum Machinery Factory, Dalian Dahua Petrochemical Co., Ltd., etc。