Application of Robot Welding

Time:2017-04-12 Views:550

Welding robot mainly includes two parts: robot and welding equipment. The robot consists of a robot body and a control cabinet (hardware and software). The welding equipment, such as arc welding and spot welding, is composed of a welding power source (including its control system), a wire feeder (arc welding), and a welding gun (clamp)

Welding robot mainly includes two parts: robot and welding equipment. The robot consists of a robot body and a control cabinet (hardware and software). The welding equipment, such as arc welding and spot welding, is composed of a welding power source (including its control system), a wire feeder (arc welding), and a welding gun (clamp). For intelligent robots, there should also be sensing systems, such as laser or camera sensors and their control devices

In the case of similar prices, try to choose products with high accuracy and high movement speed, which can be more conducive to the full play of the functions of the arc welding robot. In addition, there are also corresponding requirements for the internal control system of the arc welding robot, mainly to ensure reliable performance. In order to achieve high-quality welds by simulating human welding movements, robots are also required to have a swing function.

In order for the robot to reach any position in the workspace freely, it only needs five degrees of freedom; Of course, it would be even better if there were six degrees of freedom, so that the arc welding robot could avoid obstacles. Due to the different configurations of spatial mechanisms of robots, and in contrast, the spatial motion range of robots with parallelogram structures is smaller than that of articulated robots, it is recommended that you choose articulated robots

。

[Characteristics of robot welding]

1. Stabilize and improve welding quality to ensure its uniformity..

2. The working conditions of workers have been improved.

3. Improve labor productivity. Robots have no fatigue and can be continuously produced 24 hours a day. In addition, with the application of high-speed and efficient welding technology, the efficiency of using robots for welding has been significantly improved.

4. Clear product cycle, easy to control product output.

5. Stabilize and improve welding quality to ensure its uniformity.

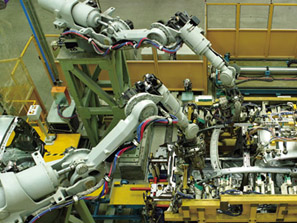

Partial application diagram of welding robot in the entire production process

In a fully automated production line, the functions of welding robots can be displayed as much as possible, which is also the goal that welding robots are generated to achieve. The manufacturing of welding robots is to make technology not far away, make life easier, and make society more advanced; Achieve high and new technology and share it with everyone!